- Home Page

- Company Profile

-

Our Products

- Fire Sleeve

- Coated Glass Fabrics

- Acrylic coated fiberglass fabric

- Neoprene coated fiberglass fabric

- PTFE coated fiberglass fabric

- PTFE impregnated fiberglass fabric

- Vermiculite coated fiberglass fabric

- Graphite coated fiberglass fabric

- Heat treated fiberglass fabric

- Weave lock fiberglass fabric

- Wire reinforced fiberglass fabric

- High temperature treated fiberglass fabric

- PVC coated fiberglass fabric

- Silicone Coated Fiberglass Fabric

- Silicone Calendered Fiberglass Fabric

- Polyurethane Coated Fiberglass Fabric

- Aluminized Fiberglass Fabric

- Silica Fiber Products

- Fiberglass products

- Ceramic Fiber Products

- Basalt Fiber Products

- Welding Blanket

- Expansion Joint Fabrics

- Insulation Jacket Fabrics

- Coated Fabrics

- Other Fiber Products

- Contact Us

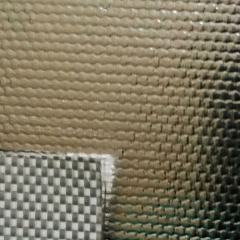

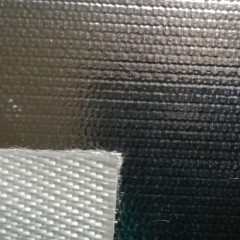

0.43mm Aluminium Mylar laminated fiberglass fabric

Product Details:

- Product Type WFF1041AM

- Usage Used to make fire suits, gloves, etc. which ask for flexibility in stitching and folding without broken

- Width 1,1.5 Meter (m)

- Length 50,100 Meter (m)

- Weight 480 GSM (gm/2)

- Size Thickness 0.43mm

- Material Aluminium Mylar lamination for fire suit

1.00 - 5.00 USD ($)/Square Meter

X

0.43mm Aluminium Mylar laminated fiberglass fabric Price And Quantity

- 1.00 - 5.00 USD ($)/Square Meter

- 500 Square Meter

0.43mm Aluminium Mylar laminated fiberglass fabric Product Specifications

- Thickness 0.43mm

- Constructed from a high temperature base filament/texturized fiberglass fabric which is then coated with highly reflective polished aluminum

- 480 GSM (gm/2)

- Used to make fire suits, gloves, etc. which ask for flexibility in stitching and folding without broken

- Used for aerospace, marine, chemical industrial, power plant, automotive, construction, pipling flexibility and sealing industry

- Aluminium Mylar lamination for fire suit

- 1,1.5 Meter (m)

- One side coated with Aluminum foil/mylar film

- 50,100 Meter (m)

- WFF1041AM

0.43mm Aluminium Mylar laminated fiberglass fabric Trade Information

- Telegraphic Transfer (T/T)

- 5000 Square Meter Per Day

- 2 Week

- Yes

- Free samples are available

- Carton,Pallet

- Western Europe Eastern Europe Middle East Central America South America Asia North America Australia Africa

- All India

- SGS,UL,ISO,NFPA

Product Description

Aluminium Mylar laminated fiberglass fabric is more durable than aluminium foil laminated fiberglass fabric, popularly used to make fire suits, gloves, etc. which ask for flexibility in stitching and folding without broken.Constructed from a high temperature base filament/texturized fiberglass fabric which is then coated with highly reflective polished aluminum. The aluminum foil coating melts at 1220degree F/ 660degree C, however it does take some time for the aluminum foil to absorb enough heat to melt,thereby it can withstand short exposure to the higher temperatures. The basic fiberglass fabric is 1000degree F/537degree C, while adhesive will burn-off or vaporize at temperatures above 300degree F/148degree C (SuperTemp adhesive resist 280degree C continuously is available by request).

Properties:

One side coated with Aluminum foil/mylar film. Protection from intense radiant heat

Reflects more than 95% of the radiant heat that contacts its surface

Excellent radiant heat protection from sources such as super-hot metal slabs, proximity to liquid metal, infrared heaters, open flame / plasma or engine exhaust manifolds is a concern

Applications:

Serve as a welding defender, heat protection quilt, foundry splash protection

Conveyor belt and expansion joint

Chemical corrosion resistance, packing material

Used for aerospace, marine, chemical industrial, power plant, automotive, construction, pipling flexibility and sealing industry.

PSA(pressure sensitive adhesive) Available

This fabric is also available with a self-adhesive backing.The adhesive is water adhesive based, and will burn-off or vaporize at temperatures above 300degree F/148degree C.If prolonged use of the self-adhesive fabric above 300degree F/148degree C is desired, then alternate securing methods such as fasteners, wire or clamps should be used.Personnel should avoid inhaling fumes from the PSA.

We have a SuperTemp adhesive can work at temperature 280degree C continuously.

Enter Buying Requirement Details

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free